CASE STUDY

Executive Summary

AI Energy Partners deployed Navigator in a major European Utility to validate and optimize its significant savings potential.

Over a 2 year period, the utility achieved operating efficiencies and CO2 emission reductions that exceeded 1%. Senior plant engineers confirmed that Navigator was effective, resulted in immediate ROI, and could be quickly deployed with no additional hardware.

CASE STUDY

Executive Summary

AI Energy Partners deployed Navigator in a major European Utility to validate and optimize its significant savings potential.

Over a 2 year period, the utility achieved operating efficiencies and CO2 emission reductions that exceeded 1%. Senior plant engineers confirmed that Navigator was effective, resulted in immediate ROI, and could be quickly deployed with no additional hardware.

“It can be determined with high accuracy that the use of the AI Energy Partners’ technology will result in an average efficiency improvement from 1.23% to 3.05%.”

Key Findings

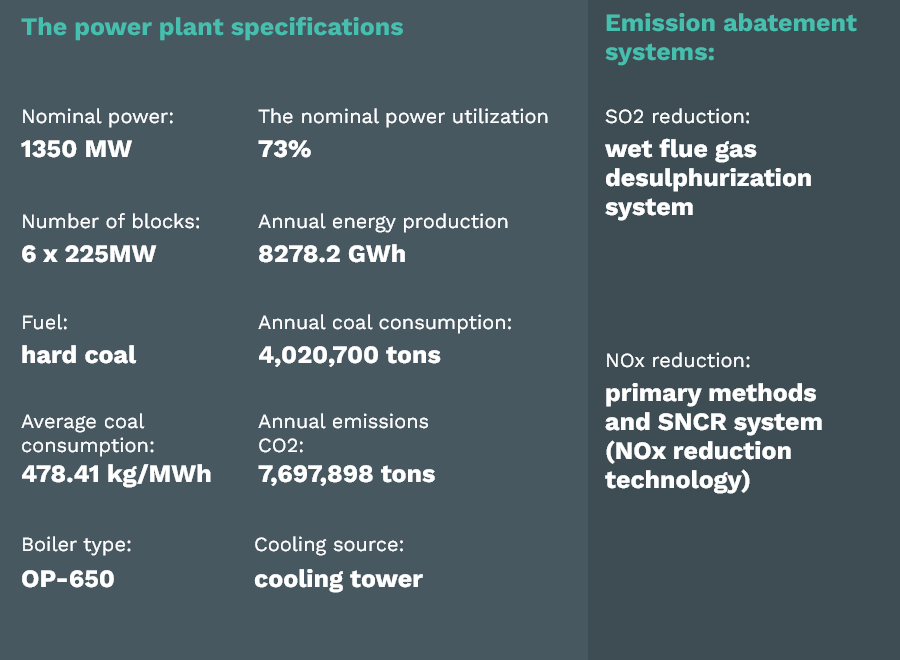

Navigator has been deployed for 2 years in a standard coal-fired power plant with six 225MW units at a leading Polish energy company.

Rigorous continual testing by senior plant engineers and outside consultants was undertaken. The results of fuel consumption reduction, emission reduction and operating savings have been audited and verified by a third party.

Due solely to Navigator's deployment, annual projected operating cost reductions at the plant exceeded $12 million USD as a result of substantially reduced coal consumption and related CO2 emissions.

Navigator's ease of use and effectiveness enabled senior plant engineers to develop new strategies for real-time control of heat rate deviation and related emission reduction.

Key Findings

Navigator has been deployed for 2 years in a standard coal-fired power plant with six 225MW units at a leading Polish energy company.

Rigorous continual testing by senior plant engineers and outside consultants was undertaken. The results of fuel consumption reduction, emission reduction and operating savings have been audited and verified by a third party.

Due solely to Navigator's deployment, annual projected operating cost reductions at the plant exceeded $12 million USD as a result of substantially reduced coal consumption and related CO2 emissions.

Navigator's ease of use and effectiveness enabled senior plant engineers to develop new strategies for real-time control of heat rate deviation and related emission reduction.

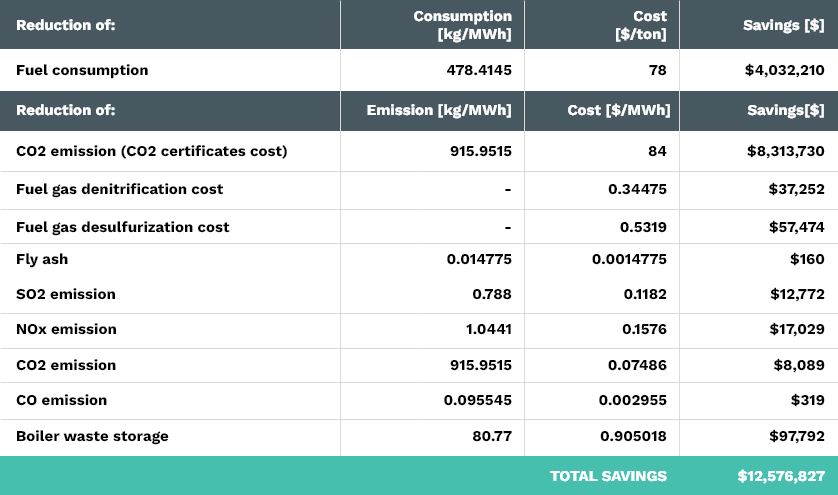

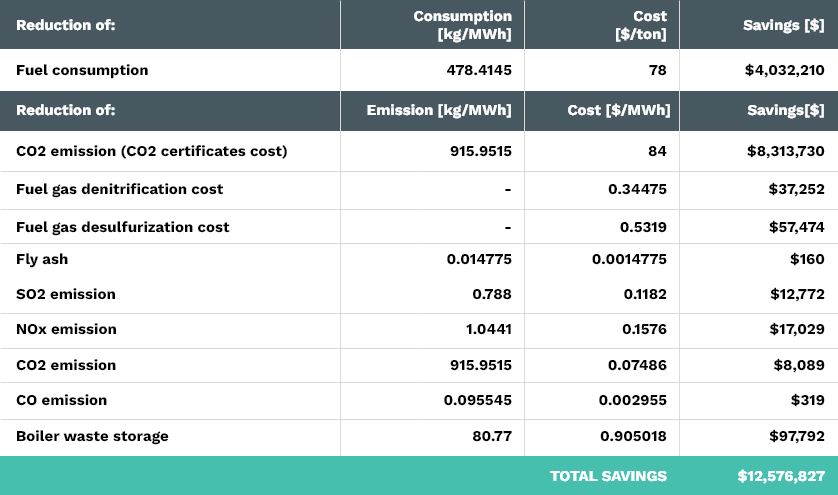

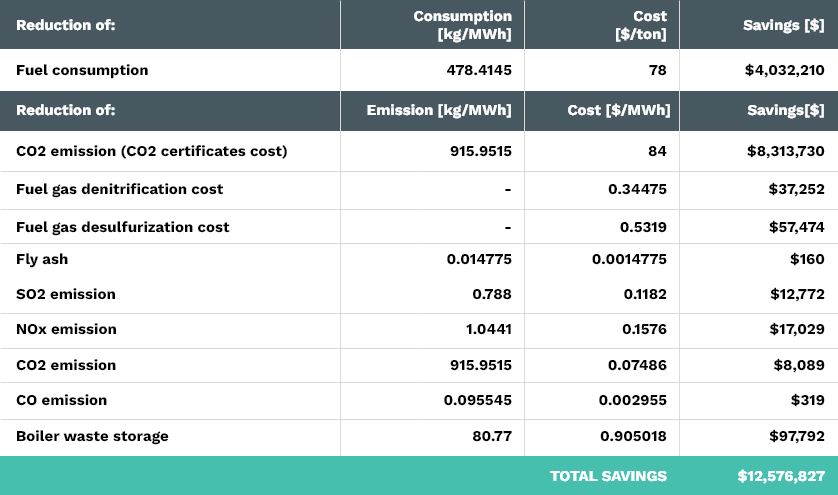

Performance Data - Annualized Savings

This chart shows the substantial ROI which will be generated by just a 1% reduction of fuel consumption. The European plant will realize a savings on such fuel consumption alone of over $4 million (with cost per ton of only $78). These significant savings are achieved solely as a result of Navigator’s AI recommended efficiencies of the plant’s existing systems. In the case of the European utility, it would have been required to pay additional European Carbon credits totaling over $8 million for a total projected annualized savings of $12.5 million per year.

Performance Data - Annualized Savings

Plant Parameters

The deployment did not require any additional hardware investment by the utility company. Therefore, Navigator is able to be deployed at low cost and fully operational in just a few months.